Products

PRODUCT CENTER

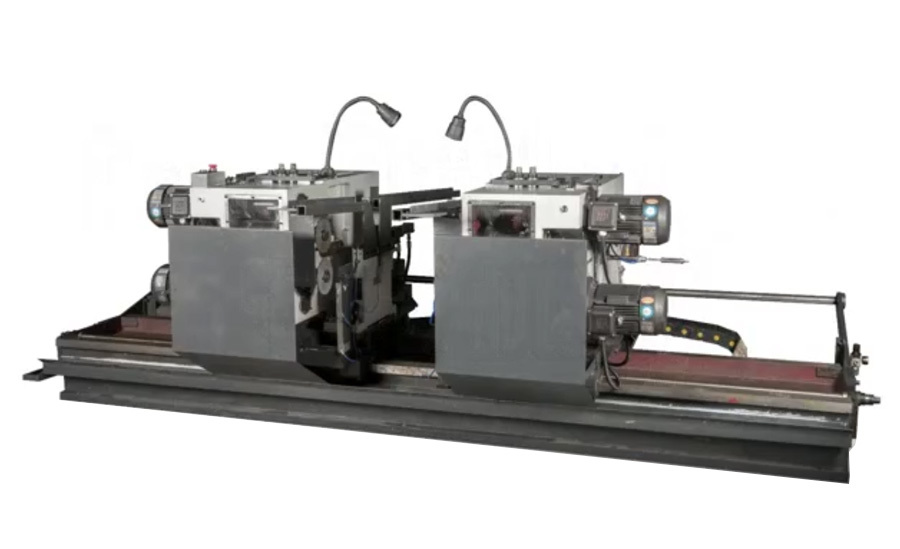

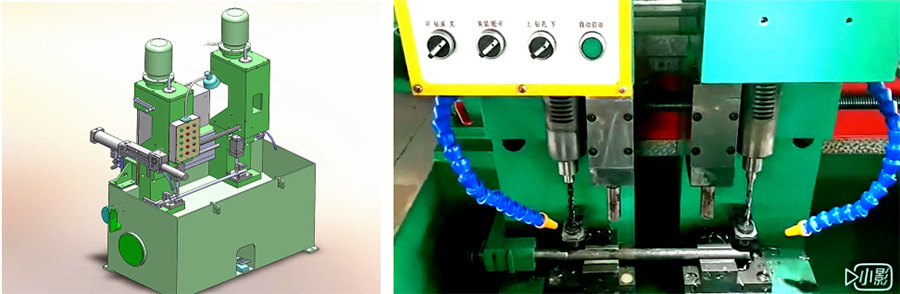

Double-headed drilling machine for roller shafts

Drilling holes at both ends of the roller shaft simultaneously increases efficiency by 3-5 times compared to traditional single-spindle drilling machines.

Key words:

Classification:

Telephone:

E-mail:

Product Details

Features

The roller shaft is drilled at both ends simultaneously, which improves efficiency by 3-5 times compared to traditional single-spindle drilling machines. It is easy to adjust and operate. The roller shaft material is hydraulically clamped, and the drilling is hydraulically fed, automatically returning after drilling is complete. It has a foot-operated switch; one press automatically completes the entire processing. Ordinary personnel can be competent for the position, and skilled workers are not required.

Composition

It consists of three major parts: electromechanical and hydraulic. Mainly includes: left housing, right housing, bed body, drill head hydraulic feed mechanism, hydraulic clamping vise and positioning plate, main shaft and drill bit, vertical guide rail, operation station, electrical control box, foot switch, hydraulic oil tank and system, cooling system, etc. Full gear transmission structure.

Technical Parameters

SGZ-Ⅱ Type Roller Shaft Double-Ended Drilling Machine

| Serial Number |

Parameter Name |

Unit |

Parameter |

Note |

| 1 |

Length × Width × Height |

mm |

1600X1150X2150 |

|

| 2 |

Weight |

kg |

1800 |

|

| 3 |

Total Power Configuration |

kw |

7 |

|

| 4 |

Roller Shaft Processing Diameter |

mm |

Φ20-Φ45 |

|

| 5 |

Roller Shaft Processing Length |

mm |

150-800 |

|

| 6 |

Production Capacity |

pcs/shift |

500-800 |

Related to shaft diameter |

| 7 |

Number of Operators |

Person |

1 or other positions concurrently |

|

| 8 |

Shaft Clamping Method |

|

Hydraulic Clamp |

|

| 9 |

Drilling Feed Rate |

|

Hydraulic stepless adjustable |

|

| 10 |

Voltage |

|

380V three-phase AC |

|

| 11 |

Drill Bit Specification |

|

Taper shank Φ8-Φ16 |

Drilling speed 3 levels |

| 12 |

Hydraulic System Pressure |

Mpa |

6.3 |

|

Operation

First, set the size according to the parameters of the roller shaft, that is, move the right housing to the required position. The movement of the right housing is completed by the handwheel on the right side, and the left housing is fixed. Turn on the power switch, place the roller shaft in the hydraulic clamping vise and close to the positioning plate, step on the foot switch, the hydraulic clamping vise clamps the roller shaft, and the main shaft and drill bit rotate at the same time. The drill bit hydraulic feed mechanism feeds, and after reaching the set depth, drilling is completed, and then the entire system automatically returns to its initial state. There are two operation modes: manual and automatic.

Previous Page

Related Products

Product Consulting

If you are interested in our products, please leave your contact information, we will contact you as soon as possible, thank you!