Products

PRODUCT CENTER

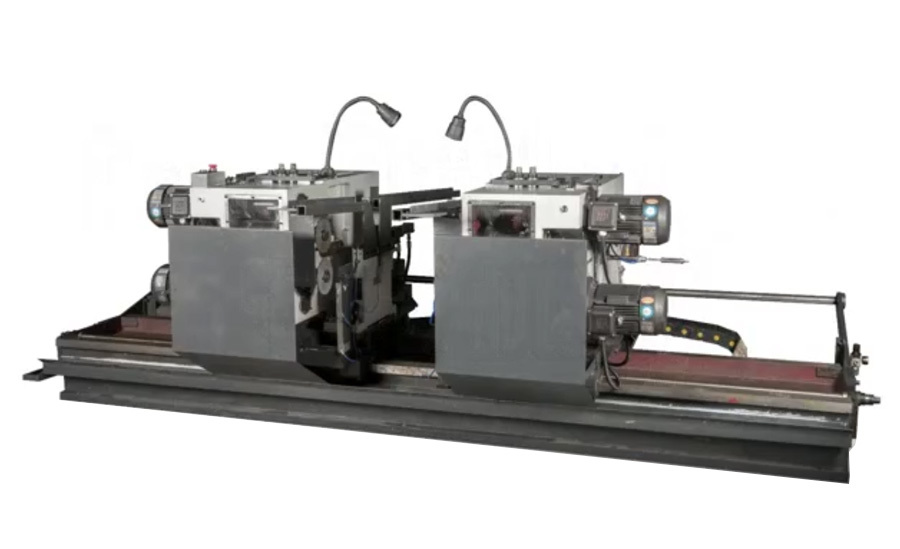

Numerical control machine tool for cutting roller tube

The head drive motor is powered by a variable frequency drive (VFD) for stepless speed regulation. The roller tube cutting range is Φ89-Φ159.

Key words:

Classification:

Telephone:

E-mail:

Product Details

The belt-type pipe automatic feeding rack automatically feeds the pipe. The CNC infeed section automatically connects the pipe and clamps it internally. It automatically feeds according to the set value and program. The roller pipe cutting CNC machine head automatically completes pipe clamping, cutter rotation, cutting. The cut pipe is conveyed, sorted, and lifted by the pipe sorting and storage self-lifting rack for the No. 1 finger of the planar transfer manipulator to grasp.

The CNC infeed section moves along the linear guide rail installed on the machine body via rack and pinion transmission. The clamping head of the CNC infeed section enters the inner hole of the pipe to clamp the inner wall. The clamping head is installed on the cantilever, and the clamping head can enter the machine head bore. The remaining amount after cutting is small; the CNC infeed section adopts closed-loop control to reduce transmission error and improve the cutting accuracy of the pipe.

A scrap collecting mechanism is provided on the side of the machine tool to collect scrap. The machine head flying knife disc has 2 knife positions. During cutting, the pipe does not move, and the flying knife disc rotates and chips, reducing vibration, improving cutting accuracy, and reducing energy consumption. It is equipped with a chip truck to collect iron chips.

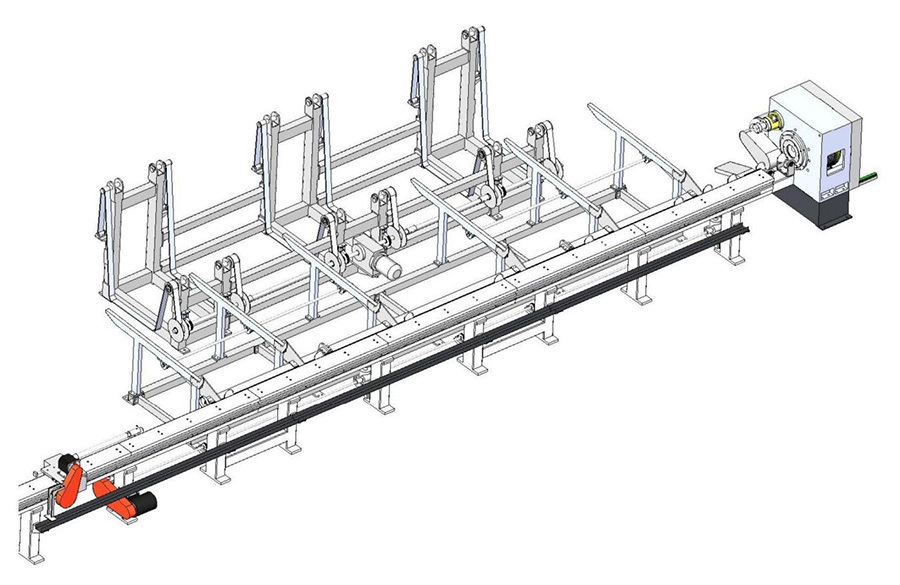

The belt-type pipe automatic feeding rack consists of a receiving rack, a storage rack, and a lifting mechanism. Bundles of steel pipes are placed in the receiving rack. After manual unbundling, the receiving rack loads, the storage rack feeds, and the lifting mechanism lifts the materials. The series of actions are program-controlled and cooperate with the roller pipe cutting CNC machine tool to achieve automatic operation.

Belt-type pipe automatic feeding rack, roller pipe cutting CNC machine tool, pipe sorting and storage self-lifting rack

The machine head drive motor is powered by a frequency converter for stepless speed regulation. The roller pipe cutting range is Φ89-Φ159. According to different diameters, the motor speed is set via the frequency converter.

The pipe sorting and storage self-lifting rack automatically completes the conveying, sorting, storage, and self-lifting positioning of the pipes for the 90° rotating manipulator to clamp the pipes. If one pipe is cut, the CNC infeed section automatically returns to the tail and enters the next cycle. The main function of the pipe sorting and storage self-lifting rack is to store pipes, ensuring uninterrupted operation of subsequent boring processes during the automatic return of the CNC infeed section to the tail end in preparation for cutting the next pipe.

Technical Parameters

Belt-type pipe automatic feeding rack, roller pipe cutting CNC machine tool, pipe sorting and storage self-lifting rack technical parameters

| Serial Number |

Parameter Name |

Unit |

Parameter |

Note |

| 1 |

Length × Width × Height |

mm |

12100×5000×2040 |

Including belt-type pipe automatic feeding rack |

| 3 |

Power Configuration |

kw |

11+1.5+3+0.36+0.55+2.2 |

|

| 4 |

Pipe Cutting Specification Φ |

mm |

89 108 127 133 159 194 219 |

|

| 5 |

Pipe Cutting Length |

mm |

275-2000 |

Digital Setting CNC Feed |

| 7 |

Accuracy/Roughness |

|

Length error ±0.30/500 /Ra6.3 |

|

| 8 |

Speed Regulation Method |

|

1:2.5 |

Frequency Converter |

| 9 |

Power Supply |

|

380V three-phase five-wire AC |

|

| 10 |

Hydraulic System Pressure |

Mpa |

4 |

|

| 11 |

Steel Pipe Raw Material Length |

|

6m-9 |

|

| 12 |

Steel Pipe Wall Thickness |

|

2.75-6mm |

|

| 13 |

Steel Pipe Material |

|

20#、Q235 |

|

Previous Page

Next Page

Related Products

Product Consulting

If you are interested in our products, please leave your contact information, we will contact you as soon as possible, thank you!