Products

PRODUCT CENTER

Idler roller fiber laser marking machine

Key words:

Classification:

Telephone:

E-mail:

Product Details

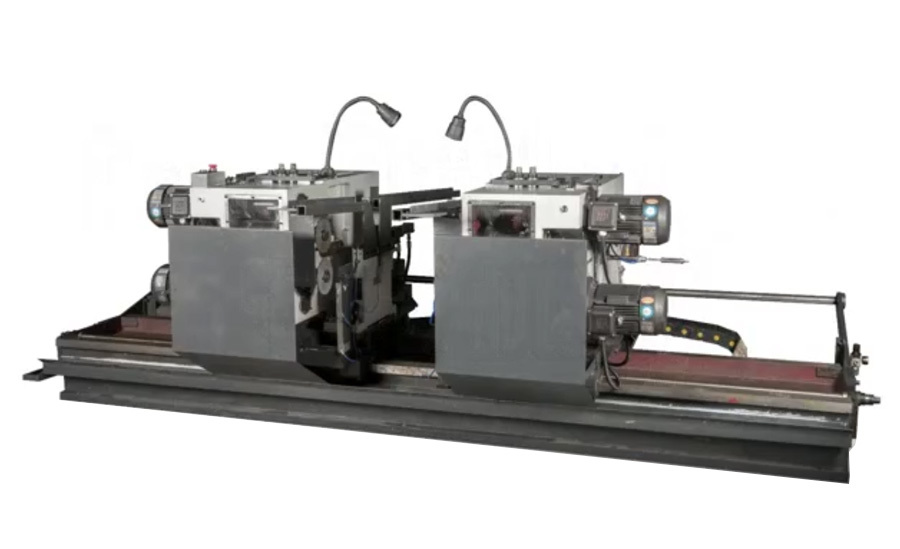

The function of the idler roller dynamic rotary running-in machine is to eliminate the internal stress after the idler roller is pressed, allowing the grease in the bearings and seals to be evenly distributed, so that the idler roller rotates flexibly. During the idler roller rotary running-in process, radial vibration is applied.

Machine composition: bed, transmission assembly, control box, touch screen control station, left and right boxes, tapered headstock, roller body support, foot switch, 2 pneumatic vibrators, 2 axial pushing devices. Programming technology is used to control the operation of the equipment.

Remarks: This diagram shows the configuration of the independent testing unit. If it is configured in a fully automatic idler roller production line, the front and rear frames need to be removed.

Idler roller dynamic rotary running-in machine, idler roller three-item performance CNC testing machine, idler roller fiber laser marking machine

Idler Roller Dynamic Rotary Running-in Machine Technical Parameters

| Serial Number |

Parameter Name |

Unit |

Parameter |

Note |

| 1 |

(Length × Width × Height) |

mm |

4300×1000×1600 |

|

| 2 |

Weight |

kg |

1100 |

|

| 3 |

Power Supply |

|

Five-wire three-phase ~380V 50Hz |

|

| 4 |

Power Configuration |

kw |

2.2 |

|

| 5 |

Rotary Running-in Speed |

r/min |

1450 |

Complies with GB/T10595-2017 national standard |

| 6 |

Idler Roller Diameter |

mm |

Φ89-Φ219 |

|

| 7 |

Idler Roller Length |

mm |

275-2000 |

|

| 8 |

Production Capacity |

pcs/shift |

500 |

Affected by auxiliary processes |

| 9 |

Number of Operators |

Person |

1 |

2 persons for large-size idler rollers |

| 10 |

Pneumatic System Pressure |

Mpa |

0.7 |

|

| 11 |

Turbine Vibration Parameters |

|

Vibration frequency 13Hz Vibration force 7.15N |

|

| 12 |

Running-in Time |

s |

15-900 |

Can be manually set |

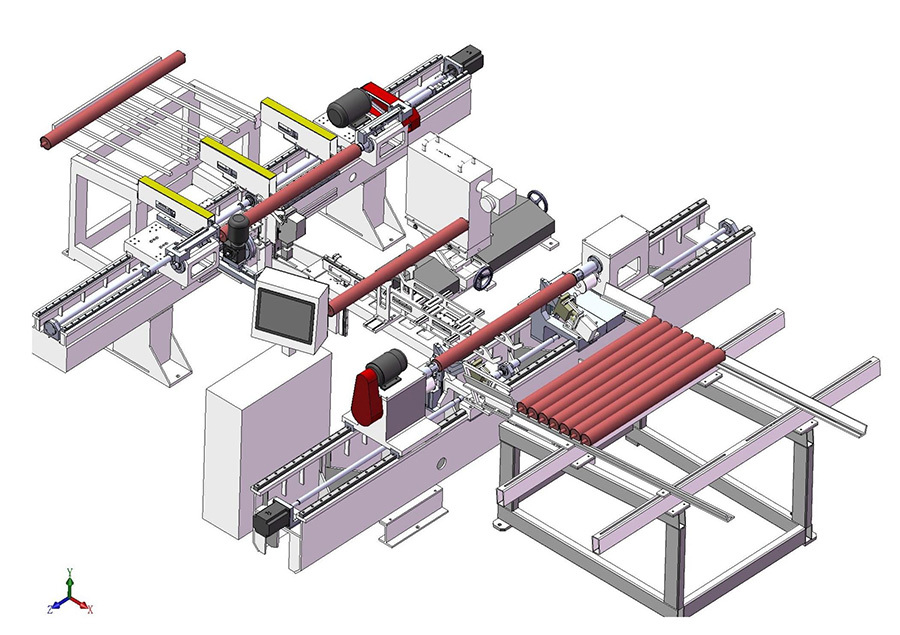

The idler roller three-item performance CNC testing machine is a testing equipment for the radial roundness, axial runout, and rotational resistance of the idler roller, referred to as three items. The testing cycle is ≤50s, and the three items of the roller are automatically measured. The equipment is controlled by PLC. The roller detection data is automatically generated and can be exported via a USB port. The testing method complies with the GBT10595-2017 standard.

Idler Roller Three-Item Performance CNC Testing Machine Technical Parameters

| Serial Number |

Parameter Name |

Unit |

Parameter |

Remarks |

| 1 |

(Length × Width × Height) |

mm |

3800×1000×1200 |

|

| 2 |

Power Supply |

|

Five-wire three-phase ~380V 50Hz |

|

| 3 |

Power Configuration |

kw |

0.75+1+0.18 |

|

| 4 |

Shaft Φ |

mm |

20 25 30 35 40 45 |

|

| 5 |

Idler Roller Length |

mm |

275-2000 |

|

| 6 |

Pneumatic System Pressure |

Mpa |

0.7 |

|

| 7 |

Weight |

kg |

1000 |

|

Axial runout. Detected using a magnetic scale, the resolution of the reading head is 0.005mm/5v.

Radial roundness. Using a KPZ34 circular displacement sensor, this miniature displacement sensor is designed for direct absolute measurement, with a stroke of 100 mm. Equipped with an external transducer, powered by 24V, analog output: 0-5V, 0-10V, 1-20mA, 0-20mA, 4-20mA, digital output RS485, RS232.

Rotation resistance detection. Using an L6D-3KG type load cell, RW-ST01D[RS485] transducer, sensitivity (mV/V)2.0±0.2, load cell comprehensive error ≤±0.030%F.S.

The marking position is on the side of the bearing seat or the end face of the shaft head. The marking content can be numbers, icons, etc.

Idler Roller Fiber Laser Marking Machine Technical Parameters

| Main Parameters |

|

| Name |

Fiber Laser Marking Machine |

| Marking Range |

220mm*220mm |

| Engraving Range |

220mm*220mm |

| Maximum Scanning Speed |

≤7000mm/s |

| Marking Repeatability |

±0.002mm |

| Laser Wavelength |

1060nm |

| Operating System |

WinXP Winds7 |

| Control Interface |

Standard USB |

| Minimum Character |

0.2mm |

| Minimum Line Width |

0.01mm |

| Beam Quality M2 |

M2<2 |

| Laser Output Power |

≤30W |

| Laser Repetition Rate |

20KHz-200KHz |

| Cooling System |

Air Cooling |

The idler roller fiber laser marking machine consists of a bed, a fiber laser marking machine, an industrial computer, and a printer. It is controlled by a system program to achieve marking.

Set labeling content in the system software. The labeling content is “LOGO#year#month#day000”, and the labeling content number automatically increments. The labeling content is also the identity code of the idler roller. The detection data and identity code correspond one-to-one, generating tabular data stored in the system for easy printing, uploading, and quality traceability.

Previous Page

Next Page

Previous Page

Next Page

Related Products

Product Consulting

If you are interested in our products, please leave your contact information, we will contact you as soon as possible, thank you!